cnc press brake

Shenchonggroup

CNC PRESS BRAKE

The CNC Press Brake is the most popular type in the market. It has higher accuracy and efficiency than the torsion bar NC hydraulic press brake. Under the synchronization of full closed loop feedback control, the operation is stable and reliable.

Application scenarios

Application scenarios of cnc press brake:

- All industries requiring sheet metal bending processing.

- Popular in high temperature areas, such as Southeast Asia, Southern China and other countries or regions near the equator.

- Workshops close to streets and factory with strict noise control.

- Enterprises pursuing green, environmental protection, and energy saving initiatives.

- Combine with robot (automatic bending cell) for intelligent factories to obtain higher efficiency.

USE OF CNC PRESS BRAKE:

- Decorations

- Kitchenware

- Containers

- Cabinets

- Carriages

- Boxes

- Aerospace

- Buildings

- Elevators

- Energy

- Towers

- Poles

- Environmental protection equipment

- Stainless steel doors and windows

- Machinery manufacturing

- Electrical equipment

- Steel structures

- Automobiles

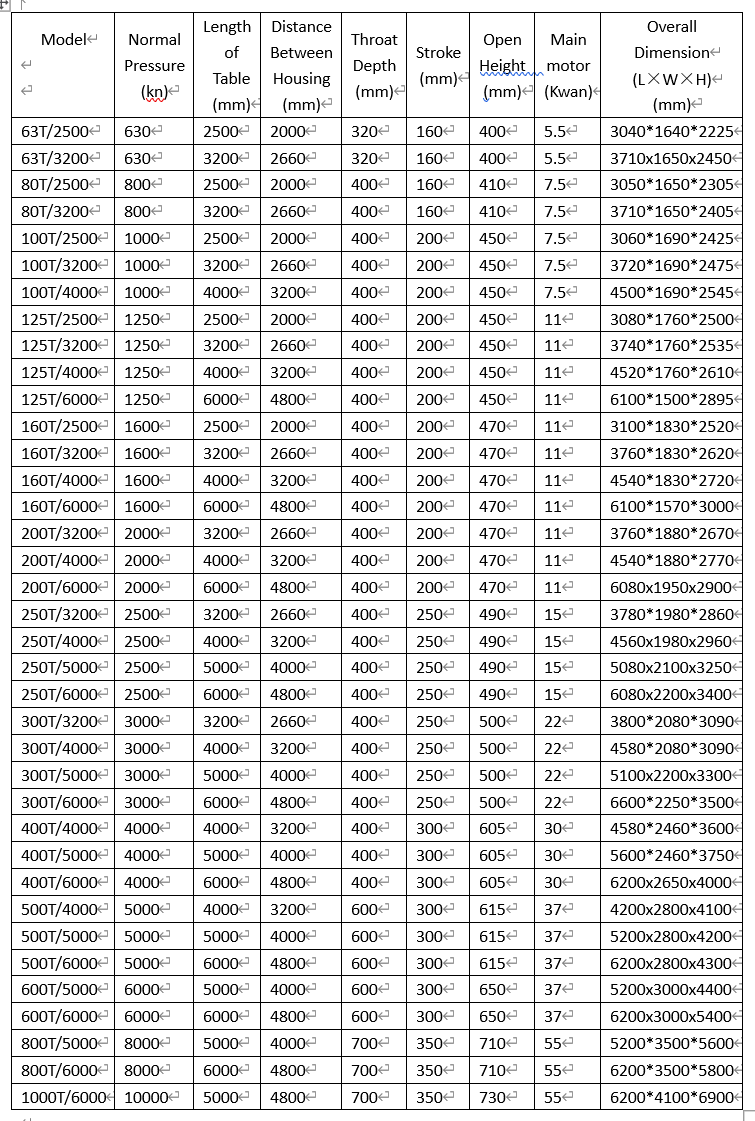

SPECIFICATIONS OF CNC PRESS BRAKE:

Technical Features of cnc press brake:

- Good stability of the frame: all steel plate welding with vibration after tempering to eliminate stress.

- Upward bending design: low noise level and stable working condition.

- Double guide rail structure: sliding block runs more smoothly.

- Slow return function: users can better control the sheet metal.

- The bottom dead center has holding time and can be programmed for various precision requirements of different parts.

- CNC controller controls the machine tool synchronization through electro-hydraulic proportional servo system, which can bend under an unbalanced load.

- Features an anti-throat deformation system to ensure the bending accuracy.

- Standard model: 4+1-axis. Multi-axis available: 5-axis, 6-axis, 7-axis, 8-axis.

- CNC controlled back gauge can bend complex work pieces.

- The bending speed is adjustable up to 180-200 mm/s.

- European brands controllers available: DELEM, CYBLEC, ESA, ELGO.

- Comfortable operation and state-of-the-art technology significantly improve the bending efficiency.

Contact us today

Our experts are ready to help and will get back to you as soon as possible. We look forward to hearing from you!