servo press brake

Shenchonggroup

SERVO PRESS BRAKE

Servo press brake is the latest generation bending machine. Our oil electric hybrid CNC press brake is a real pump controlled bending machine. Its synchronization completely relies on two sets of servo pump systems. Independent AC-servo motors drive high efficiency bi-directional hydraulic pumps to provide extremely fast bending speeds and ultra-high precision.

Application scenarios

Application scenarios of servo press brake:

- All industries that require sheet metal bending processing.

- Popular in high temperature areas, such as Southeast Asia, Southern China and other regions near the equator.

- Workshops close to streets and factories with strict noise control.

- Enterprises pursuing green, environmental protection, and energy saving initiatives.

- Combine with robot (automatic bending cell) for intelligent factories to obtain higher efficiency.

USE OF SERVO PRESS BRAKE:

- Decorations

- Kitchenware

- Containers

- Cabinets

- Carriages

- Boxes

- Aerospace

- Buildings

- Elevators

- Energy

- Towers

- Poles

- Environmental protection equipment

- Stainless steel doors and windows

- Machinery manufacturing

- Electrical equipment

- Steel structures

- Automobiles

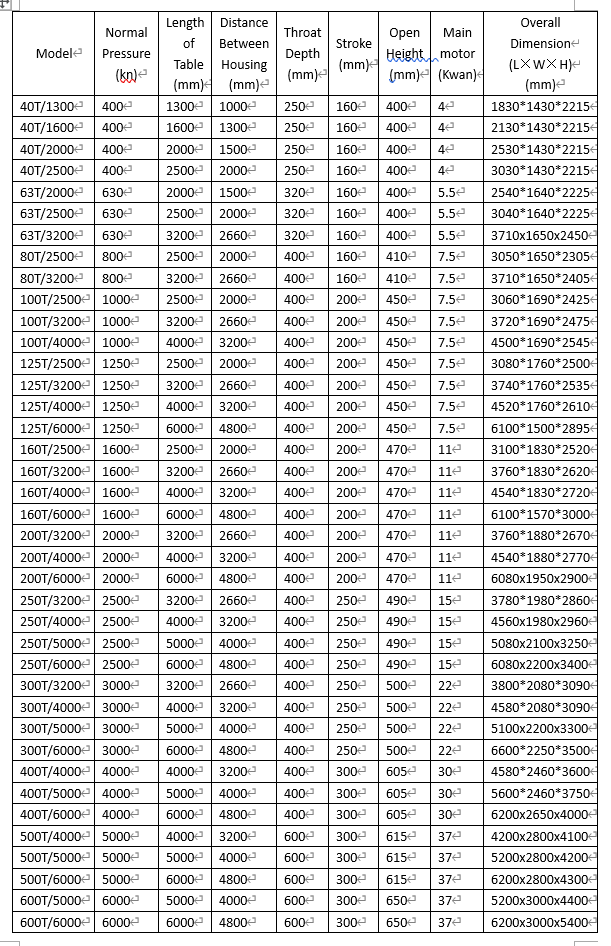

SPECIFICATIONS OF SERVO PRESS BRAKE:

Technical Features of servo press brake:

- No requirements for friction between left and right cylinders and synchronization of Y1 and Y2.

- Two servo motors control two sets of oil pumps and cylinders, respectively, to ensure the maximum accuracy of the slider.

- Good for high-precision, high-speed, high-pressure, large-stroke machine models.

- The production efficiency is extremely high. The fastest speed the machine can reach is 300mm/s.

- There is no oil leakage problem and it is energy-saving (80%-85%).

- Machine will not vibrate due to lack of proportional valve.

- Long-lasting life and low failure rate.

- Eco-friendly and silent. The noise level is less than 20 decibels.

- Hydraulic oil temperature is stable.

- Works in cooperation with robot to achieve 24×7 days unmanned bending production.

Contact us today

Our experts are ready to help and will get back to you as soon as possible. We look forward to hearing from you!